Plastic Free Zero Waste Natural Sun Cream

I’m a fan of sun hats. I’m a fan of long sleeves. I’m a fan of staying in the shade. When it comes to facing the sun, I’d much rather do any (all) of these than apply sunscreen.

I can’t bear the thought of all those chemicals in store-bought sunscreen being absorbed through my skin, and for the longest time, I’ve played Russian roulette with the sun. I didn’t apply sunscreen, and I tried to avoid getting burned. This means all of the above, and trying to dodge the sun between 10am and 4pm.

The truth is, that’s not always possible – when the weather is beautiful, I want to be outside!

Living in Australia with its fierce sun and hole in the ozone layer is very different to living in rainy England… and it means if I do get caught out and I’m not wearing sunscreen, I get burned.

Getting sunburned is not clever. Two in three Australians will be diagnosed with skin cancer by the time they are 70, and skin cancer accounts for 80% of newly diagnosed cancers every year. After being caught out and sunburned one too many times, I realised that I needed to embrace using sunscreen.

I still advocate the hat, the long sleeves and the shade, but in the times when that isn’t enough, sunscreen is better than sunburn. Chemicals aren’t good for us, but sunburn is definitely not either!

I wondered, is there a way to protect ourselves from the sun without all the chemicals… or the packaging?

Chemical Blockers versus Physical Blockers

There is a huge difference between the regular “conventional” sunscreens, which use physical and chemical blockers (and are a cocktail of synthetic chemicals), and the “natural” alternatives, which use only physical blockers.

The physical blockers used in sun cream are zinc oxide and titanium oxide. Zinc oxide blocks both UVA rays (these are the deep-penetrating rays that cause skin cancer) and UVB rays (these are the ones that cause redness and sunburn, and are the ones that SPFs are rated against). Titanium oxide is a good UVB sunblock but is not as effective as zinc oxide in blocking UVA rays.

Conventional sunscreens may also use zinc or titanium oxide as a physical blocker, but use chemical blockers too. Most chemical blockers only protect against UVB rays. These chemicals don’t sound natural or healthy, and in many cases, they’re not. Some chemicals in sunscreen are hormone disruptors, for example.

We’re not just exposing ourselves to these chemicals either – these sunscreens wash off and the chemicals enter our waterways and the ocean.

Hats are an awesome physical blocker for sun protection – but even the widest brimmed hat can’t cover everything!

Sunscreen and Nano Particles

Traditionally zinc oxide creams were very thick and created a white barrier on the skin, meaning they were hard to apply (and looked a bit silly). By making the zinc particles smaller, newer creams have come onto the market which absorb more easily and don’t leave white residue. These creams contain smaller zinc nanoparticles (classed as particles smaller than 100nm or 0.1 micron) and microfine particles (usually ranging from 0.1 micron to 2.5microns (100nm – 2500nm).

The concern with these is that they can be absorbed through the skin, and the smaller the particles, the more easily they are absorbed.

Suncreams containing zinc oxide usually state that they are “nano” or “non-nano”. Studies show that zinc oxide particles between 4nm and 20nm have the potential to be absorbed into the skin, and will be absorbed through damaged skin.

Anything smaller than 4nm will definitely be absorbed, and anything bigger than 45nm will not be absorbed. (You can read this study here.)

Conventional sunscreens use nano particles sized between 5 – 20nm – small enough to be absorbed through the skin. Non nano zinc oxide particles are larger than this and fall outside the absorption range, although some nano particles may still be present.

Most eco and natural brands use non-nano particles in their sunscreen.

Can I Buy Zero Waste Sunscreen?

Because sunscreen is heavily regulated and each batch requires testing, most small producers shy away from making their own. This makes it hard to find locally produced sunscreens that avoid the excess packaging. There is an American brand called Avasol who make a natural, non nano sunscreen packaged only in cardboard, with an SPF of 30. This is the best zero waste alternative I’ve come across. I don’t use it myself but I have friends who do.

Avasol sunscreen is an American brand that comes packaged in a cardboard tube.

What About DIY Alternatives (and how do I know the SPF)?

Yes, it is possible to make your own, but there are two things you need to know.

- You will not be able to calculate the SPF. SPF stands for Sun Protection Factor: it is a measure of the effectiveness of sunscreen against UVB rays. The higher the SPF, the more protection against sunburn the sunscreen offers. The number (SPF 20, SPF 30 etc) means how many times longer a person can stay out in the sun without getting burned relative to how long they can stay out with no sunscreen assuming 2mg per cm² is applied. Sunscreen is tested in vivo by volunteers who apply sunscreen to their skin and see how long it takes to burn (ouch). In vitro tests use a spectrometer. It is not a case of adding up the SPFs of various ingredients. The only way to find out how long homemade sunscreen will protect you for is to test it yourself.

- You will need to use a physical barrier – either zinc oxide or titanium oxide – for it to work effectively. Many plant oils have low SPFs (coconut oil and olive oil have a natural SPF of up to 7, and other plant oils have SPF properties) and applying these to the skin may help you avoid burning if you have olive skin, don’t burn and only expose skin to sun outside of the 10am – 4pm (and you live outside of Australia). Combining ingredients does not increase the overall SPF, and there is no magical high SPF plant oil. Also, their effectiveness against UVA rays (the ones that cause DNA damage and cancer) are unknown.

Zero Waste Plastic Free Sunscreen: My Recipe

My solution to the issues of chemicals, packaging and sourcing products locally was to make my own. I’ve been able to source all of these ingredients without packaging, but I realise that this may not be possible for everyone. If you can’t find ingredients sold without packaging in stores, find out if there are any local skincare producers or soap makers close to you who may be able to sell you some ingredients without packaging (that’s what I do).

You can also try switching up some of the ingredients if you have other options available to you. Whilst some ingredients can be subbed, zinc oxide is a non-negotiable – that’s what makes it sunscreen! If you need to buy ingredients in packaging, look for one that is recyclable, and remember – one container of zinc oxide will create many containers of zero waste sunscreen.

Important: this sunscreen has worked for me, and I am sharing my personal experiences. Do a small patch test when using for the first time. Avoid going in the sun at peak times and wear a hat and long sleeves. Sunscreen is a last resort, not an excuse to lay in the sun for 8 hours!

Ingredients for zero waste plastic free natural DIY sunscreen.

Ingredients:

1/2 cup almond oil (or olive oil)

1/4 cup coconut oil

1/4 cup beeswax

2 tbsp (27g) shea butter

2 tbsp non-nano zinc oxide powder

1 tsp vitamin E oil

OPTIONAL: 20 drops of essential oil (check this list first as some essential oils are phototoxic and can assist burning!)

More info on the ingredients:

Almond oil – I used sweet almond oil as that is what I use as my standard moisturizer. It is a great oil for the skin. However, it’s also far more expensive than olive oil (and according to in vitro tests, has a lower SPF of 4.7 versus the olive oil SPF of 7.5) so next time, I’ll be using olive oil.

Coconut oil – this oil is solid at less than 25°C and helps the lotion hold its form. It is very moisturising and has a natural SPF of around 7 – two properties that make it a great oil to include in sunscreen.

Beeswax – beeswax helps make this into a lotion at room temperature. This means no need to store in the fridge – handy if you want to take your sunscreen with you! It also helps make the sunscreen waterproof. Even if we’re not going in the water,the sun makes us sweat and we don’t want the sunscreen to wash off.

Shea Butter – is highly moisturising and good for dry and aging skin. It is a solid at room temperature but melts on contact with the skin, making it a good base for lotions. Look for shea butter that has been naturally processed rather than refined with hexane (a solvent).

Zinc Oxide Powder – this is the active ingredient. Zinc oxide is a physical blocker that works by reflecting / scattering UV light. It is non-irritating and suitable for sensitive skin. Zinc oxide sunscreens leave a white tinge on the skin – the bigger the zinc particles, the whiter this will be. The zinc oxide powder I used was 0.3 – 0.85 microns.

Vitamin E – this vitamin is often found in skincare products and is believed to have antioxidant and skin-healing properties, although evidence is limited and studies are ongoing. It helps prolong the shelf life of the other oils in the lotion. I used it because I have it, but you could do without.

Method:

Overheating oils can damage their properties, so I tend to melt mine one by one, starting with the most heat-resistant and working down to the least.

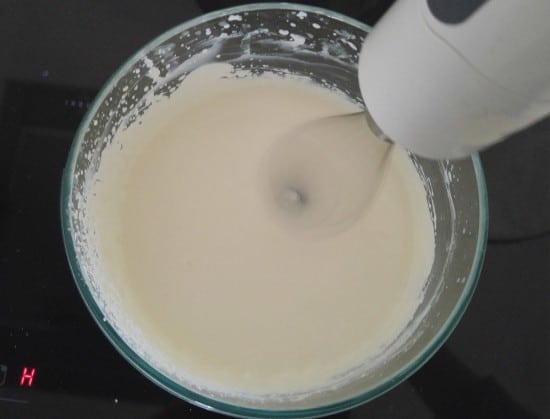

- Place a glass bowl over a pan of boiling water (a double burner) and add the beeswax. Stir until melted, and add the coconut oil. (If your coconut oil is solid, the beeswax may solidify again on contact, but continue to heat and it will melt.)

- Turn the heat off, and add the almond oil (or olive oil), using a whisk to combine. Once this is mixed in, remove the bowl from the heat.

- Add the shea butter to the bowl and stir to combine. Once it has melted, whisk the mixture. Continue to whisk until you notice the mix beginning to cool, lose transparency and change to a golden colour.

- Once the bowl feels cool and the mixture looks golden and opaque, add the zinc oxide powder using a whisk to combine.

- Add the vitamin E and essential oils, if you are using.

- Pour into a clean and dry glass jar, and seal with a lid.

Melting the beeswax over a double boiler (a glass bowl on top of a saucepan with water in it – the water is heated and that is what warms the oils)

Melting the shea butter. (The beeswax, coconut oil and almond oil have already been added.) The oils look golden and transparent. Once they begin to cool, they lose the transparency and begin to look opaque.

Once removed from the heat, the oils will cool and lose their transparency. Keep whisking to keep everything combined.

Once it’s cloudy and does not feel hot, add the zinc oxide powder. Stir in with a spoon and then whisk to combine. The powder will mix but will not dissolve so there will be some white specks.

Cream after adding the zinc oxide powder and whisking.

Now add the vitamin E and any essential oils, and whisk to distribute thoroughly. Pout into a clean glass jar and leave to cool completely.

When applying to the skin, it appears white. The more it’s rubbed in, the less white it appears. I like the white sheen that remains as it helps me see where I’ve applied the cream and which bits I’ve missed!

Zero waste plastic free sunscreen: the finished product.

You can see from the spoon that the consistency is fairly thick. Changing the oil and wax combinations will change the consistency.

If you think this seems a bit complex (and I’d love to simplify it at some stage) then there is an even simpler solution. Simply mix some zinc oxide powder into your regular moisturiser. Job done ; )

Now I’d love to hear from you! Have you made sunscreen? Do you have a recipe you’d recommend, or any great ingredients you think should be included? Have you had any recipe fails, or do have any important “do-nots” to share? Are you unsure about making your own? Have you found any great zero waste or plastic free sunscreens available for purchase that you’d like to share? Have you tried Avasol and what did you think? Anything else that you’d like to add? Please tell me your thoughts in the comments below!

[leadpages_leadbox leadbox_id=1429a0746639c5] [/leadpages_leadbox]