Compostable plastics and bioplastics – and why they aren’t the “green” solution

Bioplastics and compostable plastics are sold to us as a green, sustainable solution. The solution to what, exactly? A solution to the tons of rubbish we send to landfill every year? A reduction in our dependence on fossil fuels? A safe alternative to the hazardous chemicals we add to conventional plastics? Actually, not quite. There’s a lot more controversy to these new plastics than you might think. Did you know that some bioplastics aren’t actually biodegradable, or even recyclable? Did you know that some compostable plastics are actually made from fossil fuels? Did you know that these plastics still require additives to infer specific properties (and to encourage degradation), and these additives may still be toxic?

Confused?

So was I. Fortunately, after a heck of a lot of reading and research, I’m feeling a lot clearer about it all, and hopefully after reading this, you will be too.

First up… Bioplastics

Bioplastics are plastics made from plants. That is all it means. Bioplastics may or may not be biodegradable, may or may not be compostable, and they may or may not be toxic as a result of other chemicals used in their manufacture.

Photo credit: Kingstonist.com via Flickr. Making a difference…what does this statement mean? Is it biodegradable? Compostable? Recyclable? Messages like this are confusing!

The Terms: Biodegradable vs Degradable

Biodegradable means capable of being broken down by bacteria or other living organisms and returning to compounds found in nature. Degradable means capable of being broken down into smaller pieces. This is not the same as biodegradable. Photodegradable means capable of being broken down into smaller pieces by sunlight. Plastic generally breaks down into microplastics that do not break down further. Most plastics are therefore degradable, but not biodegradable.

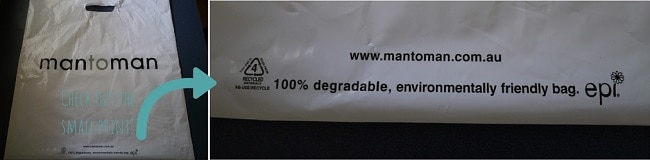

Plastic #4 (LDPE or low density polyethylene) is made from fossil fuels; it is not biodegradable, it is not compostable and it is not commonly recycled. Yes, it will degrade over time into thousands of micro pieces of plastic. How is that environmentally-friendly? Beware of greenwashing!

More Terms: Compostable vs Biodegradable

Compostable means capable of breaking down in a compost pile. Compostable plastic [as defined by the plastics industry] is “that which is capable of undergoing biological decomposition in a compost site such that the material is not visually distinguishable and breaks down into carbon dioxide, water, inorganic compounds and biomass at a rate consistent with known compostable materials”. ‘Carbon dioxide, water, inorganic compounds and biomass’ technically includes every substance in the known universe and this definition allows compostable plastic to leave toxic residues whilst still being classified as compostable.

A plastic may be biodegradable but not compostable, meaning it will break down more slowly than would be expected in a compost pile, and may not disintegrate.

Commercial Composting vs Home Composting

Compostable bioplastics may require industrial composting facilities to break down. This means an active composting phase of a minimum of 21 days, with temperatures remaining above 60ºC for at least 7 days, and regular turning. Industrial composting works much faster and better than home composting systems, which generally do not reach the same high temperatures and are not regulated.

It is not always clear with compostable packaging whether an item can be composted at home or whether it needs an industrial composting system, and whether such systems exist. BioPak cups state “compostable and biodegradable” on their packaging, but a quick look at their website finds the disclaimer “BioCup are compostable in a commercial compost facility; however this option is not widely available in Australia”. This means most BioCups used in Australia will end up in landfill, where they won’t break down.

Photo credit: Zane Selvans via Flickr. These Caltech cups are made from corn-based plastic. Caltech don’t compost these themselves (so most will be sent to landfill). To see how compostable they were, Zane put six of the cups in his very active compost pile at home (which reached 70°C a couple of times) and left them for two years. After two years, this is what they looked like.

Biodegradable Plastic

There are two categories of biodegradable plastic, and only one is made from plant materials (bioplastic). The other one is made from petrochemicals (this means fossil fuels).

Oxo-biodegradable plastic is a petroleum-based plastic made from fossil fuels (usually oil and natural gas) with metal salt additives that enables the plastic to degrade when subject to certain environment conditions. This is a two-stage process: following fragmentation, the plastic biodegrades by the action of microorganisms.

Some critics argue that oxo-biodegradable plastics are not actually biodegradable at all, because it is not clear how microorganisms actually break down the microplastics. If polymer residues remain alongside biomass, this would be disintegration rather than biodegradation.

Hydro-biodegradable plastics are plastics made from plant sources such as starch. Hydro-biodegradable plastics tend to degrade and biodegrade somewhat more quickly than oxo-biodegradable ones but the end result is the same – both are converted to carbon dioxide, water and biomass. Hydro-biodegradable plastics can be industrially composted.

PLA (polylactic acid) is the most commonly used bioplastic (polylactic acid) and costs 20% more than regular plastic. PHA (polyhydroxyalkanoate) is a more temperature resistant bioplastic, and the only bioplastic that will decompose in soil and waterways, but it is more than double the price of regular plastic and less common. PLA will not biodegrade in waterways or the ocean.

What about Recycling?

Oxo-biodegradable plastics cannot be recycled.

The bioplastic PLA can, in theory, be recycled. However, it is grouped under the plastic resin code #7, or “other” along with all other plastics that do not fit into the 6 major plastic types. (Click here to read about the different plastic categories in more detail). This means it needs to be separated from the regular recycling stream which requires technology such as infrared to be sorted correctly. In fact, PLA plastics often contaminate other plastic recycling steams.

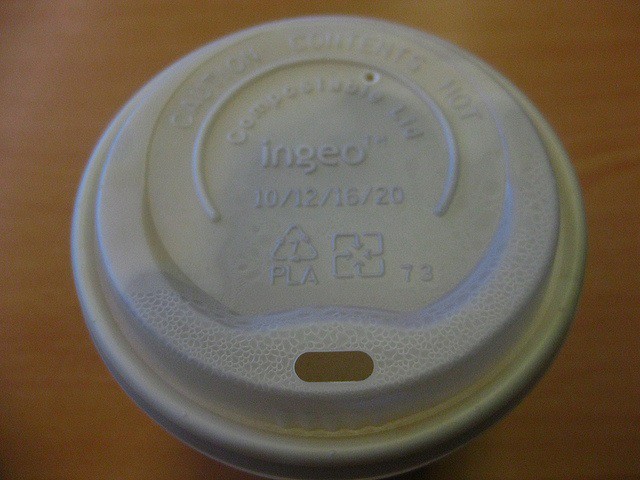

Photo credit: Fiona Moore via Flickr. A PLA ‘Ingeo’ bioplastic lid. Plastic type #7 (or ‘other’) is not recyclable.

Additives

As with other plastics, bioplastics still require additives to infer specific properties, and these additives may not be biodegradable, or tested for safety. Natureworks, the largest manufacturer of PLA in the world, state on their website “Although PLA has an excellent balance of physical and rheological properties, many additives have been combined with it to further extend the range of properties achievable and thus optimize the material for specific end use applications.” For bottles made with their PLA ‘Ingeo’ plastic, Natureworks suggest these “basic” additives are used:

- Toner and colourant: without additives ‘Ingeo’ is slightly yellow, and adding a toner can make the plastic colourless and more appealing to customers. Alternatively they may be used to make the plastic a different colour.

- A reheat additive can be used to make the heating process more efficient whilst molding the bottles.

- A UV Blocker will be required if the product is sensitive to UV light, or in order to prolong shelf life.

- Oxygen absorbers can be added to protect products sensitive to oxygen.

- A slip or process aid can be added to help prevent bottles scuffing and scratching during manufacture, packing and transport.

Anything else?

Manufacturing bioplastics is a complicated and energy-intensive process, and still depends on fossil fuels. In addition to the manufacturing processes themselves, energy is required to power farm machinery needed to sow and harvest crops used as the raw materials, and also for transportation. Fossil fuels are also used to make fertilisers and pesticides to used to increase crop yields.

Another question often raised is whether it is appropriate to use vast areas of land suitable for agriculture to grow crops to make plastic rather than for food production.

What about genetically modified food? NatureWorks, the largest PLA producer in the world, is an American company that uses corn to manufacture bioplastic. 30% of all corn grown in the USA is genetically modified, meaning GM corn is used in the manufacture of NatureWorks bioplastic. Whilst the final products are chemically altered and free from GM products, these bioplastics are still supporting the GM industry.

The Verdict?

Whether we’re talking conventional plastics or bioplastics, there’s nothing green or sustainable about using these materials for a matter of minutes and then throwing it away. Whilst bioplastics may have the potential to be composted and decrease the landfill burden, their manufacture and transportation is still hugely dependent on fossil fuels, and they still contain undeclared additives that may leach into our food, or our soils. The reality is that most of these bioplastics don’t end up in composting facilities, but head to straight to landfill, or worse, end up as litter.

If you truly want to be sustainable, don’t use plastic, and don’t use bioplastics either, especially for single-use disposable items. Simply bring your own.

[leadpages_leadbox leadbox_id=1429a0746639c5] [/leadpages_leadbox]

Yep, that’s pretty much what I teach my students about plastics in my Sustainable Design unit, to avoid it for single use and really make careful decisions for longer lasting products. And to identify it on the product! Unfortunately plant based plastics don’t have their own identification number, yet…

About GM corn in the USA;

“By 2012, 88 percent of corn (maize) and 94 percent of soy grown in the United States were genetically modified, according to the US Department of Agriculture”.

I don’t trust anything made with corn or soy from the US!

That number 7 for “other” contains so many things – they need to add some more numbers to their system!

Yes, I’ve read that if you have corn from US, assume it has been contaminated with GM : (

Thank you for such an informative and well-written post. I think “compostable plastic” is one of the most misleading, because, as you mentioned, it is often not stated whether they need a commercial facility to break down. (Which most of us don’t have access to).

I think also, we want it to be true. We want to believe it. I remember years ago being really excited about biocups – now I view them the same as the standard ones. Some of the standard ones (with the plastic lining) are made with FSC paper, so possibly they are better than these “biocups.”

We need to rethink waste and takeaway culture. Changing the material doesn’t solve the problem : (

THANK YOU so much for doing all this research and putting it together in such an easy to ‘digest’ form (sorry, couldn’t help myself!). I came across some of the depressing information about compostable plastics (bamboo doesn’t seem to compost much better) earlier this year when we were working out how to cater for all the people at our wedding :(

Thanks, I’m glad you found it useful! I really want to write a post about bamboo clothing at some point, because although it’s touted as a sustainable alternative to cotton, the way it’s processed is not very sustainable, or so I’m led to believe. I need to research it a bit more though.

We’re getting married this year, and I hoping we can use proper plates, proper glasses and just find someone to do all the washing up!

Why bioplastics are the better alternative to conventional plastic products.

Dear Lindsay,

I am the founder of BioPak and felt I should respond to your recent blog posting “Compostable plastics and bioplastics – and why they aren’t the “green” solution.

As a second generation plastic packaging producer I felt that I needed to be part of the change I wanted to see in the world. I stumbled upon the book “Cradle to Cradle – Remaking the way we make things” which opened my eyes and inspired me to take action and address the status quo of single use disposable packaging and the associated environmental impact.

I wholeheartedly agree with your statement that if you want to be truly sustainable, don’t use plastic for single use disposable items, simply bring your own.

However one should recognize that it’s not always convenient or practical to bring one’s own food service packaging and it’s in these situations that single use food service disposables are the best solution. They provide a hygienic and cost effective way to serve food and beverages to a large number of people.

Independent from the end of life disposal option of the product, if given a choice to use a product made from fossil resources or one made from rapidly renewable resources, I would suggest one made from renewables would be the better choice.

Sure the technology is still in its infancy and certainly not perfect but we should not let perfect be the enemy of good. By supporting these technologies, we are able to evolve and continue our journey towards sustainability.

I would like to clarify some of the points you made in your article.

Degradable plastics

Degradable plastics are as you stated conventional plastics with an additive that enables them to degrade. The claims are often misleading and none are backed up by any credible source. The plastic fragments pose an environmental risk and the entire basis for this type of “solution” is pure green washing preying on the uninformed members of the public. This technology and associated claims are being challenged and has been banned in many countries around the world. There are a number of position papers on the subject if you would like more information. Its certainly not something that the bioplastics industry or its members support.

Compostable plastic: In order for a bioplastic product to be certified and therefore marketed as compostable, the final product must be tested and approved by AIB Vincotte an independent and respected body. Tests are carried out to very strict and comprehensive composting standards – European Standard EN13432 or Australian Standard AS 4736. These tests ensure that the product will biodegrade completely within a specified timeframe without any toxic residues.

You mention the fact that it’s not always clear how to dispose of these products and BioPak cups did have the words “compostable and biodegradable”. As the industry along with our understanding of possible consumer confusion matures, guidelines have been implemented and marketing claims evolved to avoid intentionally misleading consumers. Until we realized that the specific compost infrastructure did not exist in Australia we believed that these claims were above board

The words “compostable & biodegradable” have been removed from all new product since January 2014. We continue to engage and work with local councils and the organics and paper recycling industry to develop more end of life options for our products. We also invest a significant amount of resources into educating consumers about the environmental impact of not only our packaging, but all packaging that ends up in landfill. We strive for honesty and transparency in everything we do and disclose the limitations along with the benefits of our products.

You mention that oxo biodegradables are biodegradable however they are degradable – this means they fragment into smaller pieces and should not be confused with biodegradable plastics.

PLA is constantly reducing in price as demand and production capacity grows. We have seen a 40% reduction in cost over the past 4 years.

What about recycling?

It’s relevant to note that when PET first entered the market, it too was not recycled, and now it has become the most recyclable plastic in the world. It’s a chicken and egg situation. Recycling options will only evolve when there is demand for a material and hence a commercial value.

PLA has more end of life options than any conventional plastic material including chemically converting it back into lactic acid the building block of PLA which means that PLA is able to be endlessly recycled without requiring new feedstock input (plant starch).

As mentioned PLA has more recycling options than any other plastic however they will only evolve once there is sufficient demand for products made from PLA. Yes it is identified by the plastics recycling code 7 and this is due to the slow adoption of bioplastics within the industry. The bioplastics associations are lobbying for a new code to identify bio based plastics. There are more than 7 different types of plastic and all plastic recycling facilities are equipped with near infrared sorting technology to separate out different plastics to avoid contamination. PLA is easily identified using this same technology and poses no threat to the plastics recycling stream.

Additives

Yes certain additives are included to process PLA and all other plastic products, however the final products are tested to compost standards and FDA food contact standards to ensure no potential toxic residues are in the material.

Anything else

Bioplastic specifically PLA is currently produced from corn. This corn is part of a crop grown specifically for industrial applications, it is the cheapest and most abundant form of plant starch and this is why it is currently the crop of choice. The amount of land used to produce starch for bioplastics is less than 0.1% of all arable land.

PLA is the first generation and the first commercially viable bioplastic in the world, it’s only been around for at most 20 years and commercial only in the last 10. Plastics have been around for over 60 years!

In future PLA will be made from non-agricultural feedstock’s and there are already a number of innovative bioplastics made from agricultural and organic waste streams including sewage, carbon dioxide and blood to name a few.

The verdict.

Wherever possible use reusable packaging.

If society continues to support products made from bio based plastics derived from rapidly renewable or organic waste streams, the industry will continue to evolve and we will ultimately develop a material that is much more sustainable than plastics derived from fossil fuels.

Plastics packaging plays a valuable role in protecting human health, and extending the shelf life of food.

Of course it’s better to reuse products and resources and that is what the new industrial revolution is all about. We are striving to learn from and work in harmony with nature in order to create a closed loop cycle where biological resources are recycled and return to nature.

Don’t accept the status quo and don’t let perfect be the enemy of good.

Hi Richard, thank you so much for taking the time to respond to my article and make such interesting points : )

It’s great to hear that you have the issue of sustainability at heart. Whilst I think some companies may hope to profit out of false “green” claims, I have no doubts that many other eco packaging companies want to make a difference. The problem is with packaging in general, and our disposable society, and this packaging heading to landfill regardless of the material.

It is frustrating that these cups COULD be composted, yet these facilities don’t widely exist. The same goes for recycling PLA – the technology is there but the sorting doesn’t happen. There should be new codes – grouping so many completely different materials under “other” doesn’t make sense. But it would be best if our consumer society just slowed down long enough to sit and enjoy the coffee in a proper cup now and then! I think everything is okay in moderation – and that is just it. There is no moderation!

I recognise that with everything there’s always compromise and it’s very hard to get “perfect”! Yes, renewable materials are better than fossil fuels. But personally, I’ll still be bringing my own cups and containers : )

There are Waste Compost Facilities in Australia.

The SMRC in WA process 5 local councils waste bins into compost, and readily breaks down compostable packaging.

See SMRC’s RRRC

Hi Claire, thanks for your comment. It’s great that these facilities exist – I only wish they were more common! The WMRC (where I live) does not offer this facility – and as you said, the SMRC only serves 5 of Perth’s councils. I know from experience that people find this bin system confusing, meaning these cups are put into recycling rather than the green waste bins, or glass is put into the green bin, meaning the resulting compost is contaminated.

Functionality and availability of these facilities aside, using anything for a single time is a waste of resources. Reusables are far better all round, in my opinion! : )

Lindsay

I try not to underestimate the power of human conversation to change the world. One of the things we need to learn is that very great change starts from very small conversations, held among people who care.

More companies, councils and governments are stepping up and addressing the issue of waste to landfill. With a global population of 7 billion and growing, the concept of waste to landfill in archaic and no longer sustainable. As resources become more scarce and more valuable, recycling will increase and landfills will be a thing of the past.

It is frustrating that recyclable products end up in landfill but this is not the fault of packaging itself, its more to do with consumer attitudes and behaviour. We have been working hard to find a better end of life option for our cups and recently made some exciting progress.

Together with paper recycling companies and local councils, we are compiling a list of areas across Australia and New Zealand where paper cups are now accepted in the waste paper recycling stream. I’m excited to report that although we are in the early stages of the project, it appears as if the recycling option is widely available.

This is only the beginning, I’m encouraged to do more by passionate individuals such as yourself, who raise awareness and question the status quo.

“Never underestimate the power of a small group of committed people to change the world. In fact, it is the only thing that ever has.” ~ Margaret Mead

This was very informative, thank you. I’ve always wondered whether there was a difference between degradable and biodegradable.

Thanks, glad you found it useful : ) Yep, degradable is a sneaky way for companies to pretend they care about the environment when doing everything the way it’s always been done >: (

Great work, Lindsay, and a really good comment section — Sandy

Thanks! It’s nice to hear from you again Sandy : )

Hi Lindsay, Are you aware of any real biodegradable single use packaging out there? As an artist I need to package works to keep them from getting dirty, especially hand made cards as people do like to touch. I don’t want to use cellophane and have heard that there is an alternative out there. Any ideas?

Fantastic article as always Lindsay.

I would suggest you research GM as carefully before repeating the sort of statements that paint GM as a negative to be avoided. It is (as with plastics) a lot more complicated than that. As a science educator, it feels like we spend as much time trying to counteract myths (aluminium is dangerous in deodorant, amber teeth beads work, degradable plastic is good, GM is evil) as we do educating.

‘Science vs’ did a good podcast on this recently that explains it all well for the layperson. I’m all for cutting back on the staggering amounts of soy and corn grown simply to support the animal agriculture industry, but GM modified bacteria and algae will most likely be producing much of our plastics and fuels in a few years time, so let’s not lump every aspect of a technology into the ‘dangerous and suspicious’ basket. The weight of evidence just doesn’t justify those suspicions.

Hi Ness, thanks for your comment. I actually have an honours degree in biochemistry, and am well aware of the complexities around genetic engineering, and indeed, how there is a lot of incorrect information out there. I just wanted to touch here on the matter that bioplastics use GM corn as it is something people often ask about. But there is plenty more to be said! Perhaps I should have left it out, rather than touch on it.

My opinion is that when a plant is genetically modified to allow patenting of seeds, increase sales of chemicals (to increase profits of a chemical company) and increase spraying of crops (which is the case with Bt corn), then that is not something I wish to support. I’m also following with interest the current research linking Bt corn to leaky gut syndrome. Personally, I’ve seen too many things considered good and safe before discovering that they are not – it’s made me a skeptic! I’d rather avoid these things until the evidence that they are good and useful is out there, as opposed to waiting for evidence to prove they are bad. That is just my opinion.

Of course, Bt corn is just one example in a complex area of research and innovation. Genetic engineering has also achieved many great things, and I agree, we shouldn’t lump it ll into one basket :)

Well said Lindsay

HI Lindsay, I love your article and as I couldn’t have said it better I have written a blog on my website and added your link. You can view it here…https://www.smoochnaturalproducts.nz/

We are advocates for zero waste and don’t use any plastic in our packaging. The more we can get the message out the better and quicker our results will be. I assumed you were happy to share as I have seen the article pop up in other places but I am more than happy to take it down if you would rather.

keep up the good work :-)

Cheers

Corrin

Very very very interesting and useful article! Thank you!

Margot – thepastelproject.com

I see a huge amount of greenwashing going on here. I think the reality is we just need to quit plastic!

Thanks for such a terrific, informative post.

The % of GM corn crop grown in the US is much higher. In 2012 it was 88%!

From my research online I can see there are compostable cornstarch plastic cups available for sale from China that are potentially more biodegradable than PLA based cups. They look different, they are not clear, and resemble flimsy beer cups. They don’t have the green logos and information printed on them like the PLA based ones. THe problem is that they are only available in quantities of 50,000 units from such sites as alibaba. Why are there NO U.S. based companies selling these? All PLA based cups seem to use the exact same company: Ingeo. Ingeo uses a mix of GMO and non-GMO corn and it is guaranteed all there cups have some GMO corn in them. Is there something going on here where we are being prevented from using a more eco-friendly option (though certainly not as attractive) because Ingeo has cornered the US market? I’m just exasperated that I cannot, and this is after about 6 or 7 hours of research online and calling/emailing companies, find a non-gmo cold cup. There has got to be an alternative to Ingeo for those of us that don’t want to support GMO farming and the conversion of farmland to make packaging! Several new materials are in the works that use food waste and degrade in water over time but right now there seems to be ZERO alternative. Thank you!

Thankyou for the article and your response to the biopak company. It is way too confusing for the consumer/citizen. As it has reached such a level of confusion I have been making more and more choices just to refuse everything.

The ellen macarthur foundation has some of the best learning material that I have seen. If you google “Upstream Innovation” you will see the bunch very short and inspiring videos. fav youtube_com/watch?v=f2uoMa_m3ZU

1 ELIMINATE

2 REUSE

3 and as last resort CIRCULATE (if we cannot eliminate, and we cannot reuse, then at least the materials should stay at work).

Unfortunately in NZ for me, the large % of business focus is still primarily on 3. Takes bold decision to shift the focus and go after ELIMINATE. Ecostore is the one trailblazer. I heard from wanaka is wanting to be the first community with zero disposal cups. I wish wellington wanted that.